Automating the Furniture Industry: 1898-1904

They had early realized that to attain their ambition of magnitude of production and a truly national scope of distribution, reliance on a purely hand made product was impossible.… Machinery must and would revolutionize the furniture industry as it was changing every other. — E. A. Stavrum, Fortieth Anniversary of the Founding of S. Karpen & Bros. Chicago: S. Karpen & Bros., 1920, 9-10. Private collection, Emily C. Rose.

After the Civil War, “technology…reduced the amount of hand labor and the cost of materials, making soft, comfortable seating furniture affordable just when ‘the million’ could aspire to have a parlor….As the demand for upholstered parlor furniture grew, machines were developed for speeding up the unpleasant tasks of cleaning, sorting, and baling the various animal hairs, moss, and tow used in stuffing … upholstered pieces. At the same time, the introduction of improved high-power looms in the textile industry continued to reduce the price of cloth while increasing the variety of weaves and textures available to the consumer.”[1] Karpen Bros. was at the forefront in utilizing and inventing equally significant time-and-labor-saving machines for the furniture industry. [2]

While Karpen Bros. profited from the new technology invented by other companies, it also patented improvements to the machine. Decades later, Karpen Bros. explained its early plan:

In the 1870s, new machines had aided the production of shaped and carved wood pieces and thin veneers.[3] Steam power was used to produce spindles by using rotating metal burrs; then carving machines with whirling knives could cut four replicas of a three-dimensional hand-carved model at one time.[4]

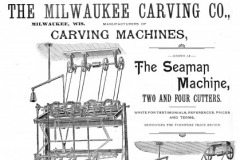

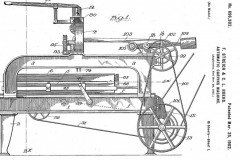

Seaman 1892 Carving Machine Patent

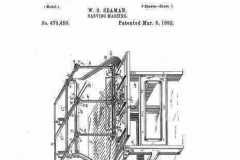

Seaman 1897 Carving Machine Patent

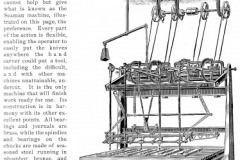

In the 1890s, carvers in Karpen’s frame factory worked with seven different carving machines, [5] using the designs of its sculptors. “All carved work was first modeled by him in plaster and the ten carving machines used these as patterns, as well as the army of hand carvers.”[6] Several of these machines were patented by the Seaman family of Milwaukee: William Seaman patented an automatic carving machine in 1892. The Milwaukee Carving Co. was granted the patent rights and protected its patent. In 1895, Alonzo Seaman applied for a patent for freehand-style carving machine; it was issued in 1897.

Automatic Carving Machine

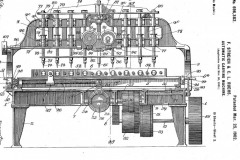

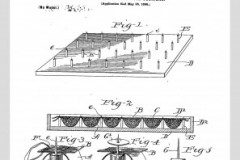

Automatic Carving Machine 1902 Patent

In 1901 Karpen Bros. “revolutionized” the wood-working industry. Its factory mechanics, Frank Streich and Charles L. Ruehs, invented a new machine, which, after being tested and improved in its factory, was patented. The 28-page US Patent application was filed on November 20, 1901 and was approved on March 25, 1902. In the application Patent No. 696,382 was assigned to S. Karpen & Bros.[7]

Karpen Bros. immediately started using the newly patented automatic carving device, which eliminated the necessity of an attendant to operate the carving machine.[8] One man could run a number of machines at the same time, and it was claimed that the multiple-spindle carving machine[9] worked 125% faster than other [hand-operated] carvers.[10] The tremendous time-savings accomplished by this machine may be imagined from the statement made that it will accomplish from twice to four times the work of the hand operated machines without the aid of an operator.[11] The operator only needed to attach new blocks of wood to take the place of those completed. [12]

Karpen Bros. boasted about the machine’s success in its factory as “a wonder in its simplicity and effectiveness,” producing “elaborating carved effects.” [13]

Karpen Bros. established a subsidiary, the Universal Automatic Carving Machine Company, before April 1902 as a New Jersey corporation.[14] Julius (the youngest brother who had received a law degree) served as its manager and secretary, and its offices were in its factory.[15] The rights to manufacture the automatic carving machines were sold to The Union Embossing Machine Company of Indianapolis, Indiana, a small company incorporated in 1895.[16] Karpen Bros. issued a catalog for “the Greatest Labor Saving Machine ever invented in wood working machinery.”[17] It offered to place the machine “in any factory at their own risk subject to the approval of the buyer before acceptance.”[18]

A machinery monthly journal featured the machine in June 1902, describing in detail the mechanics of the machine.

The furniture trade papers ran effusive copy provided by Karpen Bros. under the title “A Revolution in Wood Working.” [19] The Grand Rapids Furniture Record featured the machine and its work in a long article, illustrated by photos of four or eight identical carved pieces that were made at one cutting in about four hours. [20] It described a “truly a remarkable machine. It is almost human in its action, and observes every line of the pattern as though a human hand and mind were guiding the tractor instead of the invisible hand of mechanical genius alone.” [21]

“The machine created a sensation among the entire trade. Two machines were sold immediately after the first appearance of the ad in the papers: one machine was sold to a large table manufacturer in Detroit, and the other to a large manufacturer of chairs in Binghamton, N.Y.”[22]

The Grand Rapids Furniture Record featured the machine again in 1903 with illustrations of carved pedestals, furniture legs, and carved panels, this time putting the significance of the technology in perspective: “What the linotype machine is in the printing house, automatic carving machines will be in the furniture factory of the future.”[23]

Karpen Bros.’ factory employees, Streich and Ruehs, were issued other patents which they assigned to Karpen Bros. and the Universal Automatic Carving Machine Company. Karpen Bros. also added a new carving detailing machine that “did away with hand work and sanding on carvings after the carving machine has roughed out the design. The detailer finished the carving perfectly, leaving every small detail more accurately than it was possible for the most skilled hand carver to do the work. With the automatic carving machine and the detailing machine, one unskilled workman can accomplish more work and of a much superior quality than can be done with twenty-five skilled hand carvers.” [24]

Novelty Tufting Machine

S. Karpen & Bros.’ first effort to utilize new technology focused on upholstery tufting that had been done by hand— “slow, tedious and expensive work. A few crude efforts to do this important operation by machinery had been looked on by the trade with indifference.” [25]

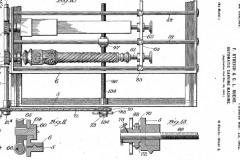

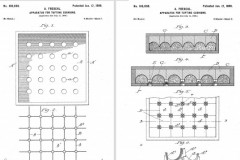

Tufting Machine 1899 Patent

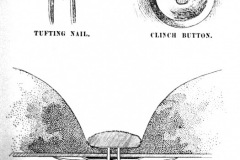

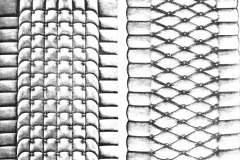

However, when Albert Freschl of Chicago invented the Novelty Tufting Machine in 1898, it was a “pronounced success from the first.”[26] Freschl applied for three patents in 1898 (US Patent 618,030; US Patent 619,685; US Patent 620,070); they were issued in 1899. Karpen Bros. was one of the first furniture manufacturers to place the machine in its factory in 1898. It was reported that “all speak highly of the process, which is, indeed, a money-making one for any users of tufting.”[27]

The furniture trade press was very impressed with the new machine as a labor-saving technology.

The tufting machine process was explained in the trade press:

An article reported an amusing anecdote regarding this new technology:

A Karpen Couch as Life Saver – Last week a window cleaner of the Hartman Furniture Co. lost his balance on the fourth floor in the alley of the concern’s building and fell down, fortunately, however, on a couch just delivered by S. Karpen & Bros. The couch, being one of those made with the Novelty tufting device, proved a life saver. The man alighted squarely on top of it, and rose up completely unhurt, so that inside of twenty minutes he was at work on the unfinished job on the fourth story. Strange to relate, the couch escaped also without the slightest damage. Could there be given a better testimonial to substantial good work.[28]

The Novelty Tufting Machine Co. granted shop rights (the rights to use the technology) to businesses throughout the country. “A complete outfit, consisting of presses and forms for tufting couches and upholstered furniture, inclusive of instructions, is rented at an annual charge of $250, or a license will be granted under all patents after the first year’s rental for $1,000. The cost of the machine depends upon the size desired.” [29] In 1899, “twenty-two of the leading furniture factories of the country [were using the machine], saving thousands of dollars. These firms were “broad minded enough to recognize its utility and great advantages over hand labor.”[30] It was claimed that one machine could take the place of twenty-five skilled workman.[31]

An advertisement from 1898 shared the Novelty Tufting Company’s marketing plan:

Novelty Tufting Machine Company at 211 Madison Street, Chicago. The machine is very simple and there is nothing to get out of order. Nearly all the parts are of wood and can be replaced at a trifling cost. In the couch department a heavier press is employed which can be operated by power or by hand. Their machines are adept for upholstering couches, lounges, Parlor furniture, office furniture, rockers and library chairs, baby carriages and invalid chairs, church, opera and hall seats and back. The interior decoration or wherever upholstering is used. Remember, no glue, no drying, no skill. If you want to see couches made, come and see them but let them know beforehand when you are coming so that they can be sure to meet you. They will not quote prices by letter. Neither will they send machines on approval nor is it necessary to send samples. They would rather pay your expenses to come where you can see for yourself what they have and make a deal with you personally. They state they will sell only a limited number of licenses. Eight couch and Parlor furniture machines at S. Karpen and Brothers, Chicago, Illinois. And they have permission from this firm to show these machines in the operation of their factory to their customers.

Boston, Massachusetts

June 23, 1898.

Novelty Tufting Machine Company, Chicago, Illinois.

Gentlemen,

I have been well repaid for my trip to Chicago and greatly surprised at the evolution in upholstering as displayed in your patent machine. It does all you claim and more. Not only in workmanship but in durability. It is everlasting as far as wear is concerned and retains its form as to beauty and comfort. I don’t see how any manufacturer can get along without it.

Yours truly,

J. Redenson and Company

Boston, Massachusetts[32]

Tufting Machine 1902 Patent

Freschl controlled the patents for the machine. Nevertheless, Karpen Bros. made improvements in the machine. In 1899 Solomon applied for a patent for an improvement for tufting cushions. When the patent was approved, he assigned it to Freschl and the Novelty Tufting Co.

A furniture trade journal predicted great changes in the industry in 1902:

The beginning, then, of an era of automatic machines in furniture and kindred industries marks an important advance towards the emancipation of the machine toilers, the lessening of the cost and the improvement of the product. The tremendous reduction in the cost of making shoes, resulting from the introduction of automatic machines, may be taken as a fair forerunner of what will happen in furniture making during the next few years. Progressive manufacturers cannot fail to grasp the importance of this invention. It bids fair to mark the most important advance ever made in the invention of woodworking machines.[33]

- Sharon Darling, Chicago Furniture: Art, Craft, & Industry 1833-1983. (New York: W.W. Norton & Co. 1984), 50. ↑

- Sharon Darling, Chicago Furniture: Art, Craft, & Industry 1833-1983. (New York: W.W. Norton & Co. 1984), 50. ↑

- American Cabinet Maker and Upholsterer, Nov. 24, 1877, 20. ↑

- American Cabinet Maker and Upholsterer, Nov. 24, 1877, 20. ↑

- Grand Rapids Furniture Record, May 1902, 187. Chicago Daily Tribune, Nov. 3, 1899, 10. ↑

- Furniture Worker, May 10, 1900, 40. ↑

- U.S. Patent, Mar. 25, 1902. No. 696,382. ↑

- Furniture Worker, Sept. 10, 1901, 33. ↑

- Furniture Worker, Nov. 10, 1901, 38. ↑

- Furniture Worker, Sept. 25, 1901, 36. Furniture Worker, Nov. 10, 1901, 38. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑

- Furniture World, Nov. 25, 1901, 17. The Furniture Journal, Dec. 10, 1901, 17. Furniture World, Dec. 19, 1901, 39. [Exact article repeated.] Furniture Trade Review and Interior Decorator, Jan. 10, 1902, 61. ↑

- US Patent 768,917, filed Apr. 19, 1902, issued Aug. 30, 1904. ↑

- “Automatic Carving Machine,” Modern Machinery, June 1902, 178-179. ↑

- Grand Rapids Furniture Record, Mar. 1903, 351-2. http://vintagemachinery.org. ↑

- Furniture Trade Review and Interior Decorator, May 10, 1902, 10. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑

- Furniture World, Aug. 21, 1902, 22. Furniture Worker, Apr. 10, 1902, 66. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑

- Furniture Worker, May 25, 1902, 25. ↑

- “The Automatic Carving Machine.” Grand Rapids Furniture Record, March, 1903, 352. ↑

- Grand Rapids Furniture Record, March, 1903, 351-2. ↑

- American Cabinet Maker and Upholsterer, June 24, 1899, 12. ↑

- American Cabinet Maker and Upholsterer, June 24, 1899, 12. ↑

- Furniture Worker, Oct. 10, 1898, 19. ↑

- Furniture Worker, Oct. 25, 1898, 20. ↑

- American Cabinet Maker and Upholsterer, June 24, 1899, 12. ↑

- American Cabinet Maker and Upholsterer, June 24, 1899, 12. ↑

- Furniture World, Dec. 15, 1898, 16. ↑

- American Furniture Gazette Special, July 4, 1898, 20. ↑

- Grand Rapids Furniture Record, May 1902, 187. ↑